Forums

Guest

|

|---|

| Welcome Guest, posting in this forum require registration. |

|

|

Torque » Torque OBD ECU Scanner » Torque Discussion / Ideas » O2 sensor voltages and rate of data sampling

| Pages: [1] |

Author Author |

Topic: O2 sensor voltages and rate of data sampling |

|---|

| Bill

Member Posts: 1 |

|

||||

| F-150Torqued

Member Posts: 437 |

|

||||

| Pages: [1] |

Page loaded in: 0.01 seconds.

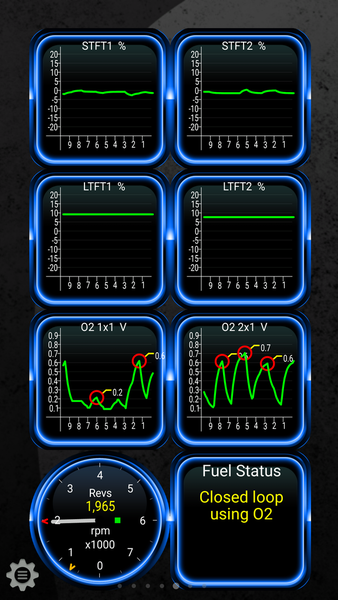

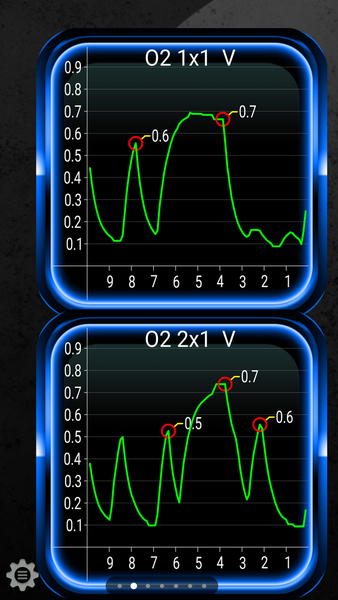

O2 sensor voltages and rate of data sampling

O2 sensor voltages and rate of data sampling